Bulk flour systems

Nationwide service, based in Tønder, near Løgumkloster.

ABTEK bulk flour systems have more than 60 years’ experience, and through development we emphasize important issues such as:

• Safe function and design.

• Gentle handling of products.

• Least possible solution maintenance.

• Flexibility.

Engineering and manufacturing company

ABTEK is an engineering and manufacturing company specializing in silo systems for flour, sugar, and other powders and granules, pneumatic and mechanical transport systems, dosing and weighing systems based on roads indicators. Either as a single system or as fully-integrated PC-based recipe management system.

The systems are delivered to bakeries, noodle factories, mills, and other food producers.

Generally, deliveries in tank wagons are cheaper for both the supplier and customer, and a much better working environment is achieved.

Our products are based on more than 60 years’ experience combined, and our development has a special focus on:

• Reliable design and function.

• Minimal maintenance.

• Flexibility.

Our unique fluidization system ensures gentle handling of the flour, the properties of the flour are improved, since the fluidization makes the flour “lighter” and improves water absorption.

As a starting point, our systems are modular, which makes them ideal for transport over long distances.

Among other things, we can offer

- Bulk Flour Systems

- Big bag unloading stations

- Minor ingredient systems

- Pneumatic Transport Systems

- Screw Conveyors

- Rotary Freeders

- Weigh hoppers

- Elektroniske Forvalgsvægte

- Recipe Management Systems

- Sifters

- Liquid Dosing System

- Sour Dough Tank

- Process Tank

- Water Mixer

- Sheet Cleaning Machine

Bulk Flour Systems

Capacity:

1,400 – 60,000 kg flour (2.3 – 100 m3)

Standard materials:

Sides in aluminum. Top and bottom and legs in stainless steel or powder coated steel.

Design:

Round or square silos, in bolted or welded construction.

Bottom:

The design depends on the product to be handled. E.g.:

– Fluidized conical bottom for delicate products.

– Vibration bottom for difficult products.

– Sluice gate or outlet gate.

Top:

The top is equipped with a filter that covers the silo’s entire cross sectional area. Alternatively, bag or envelope filters are available.

Standard equipment:

– Two inspection glasses.

– Empty and full indicator.

– Control function for connection of full indicator.

– Complete electrical control panel.

Feeding tube:

Aluminum tube (standard) or stainless steel tube with coupler and end cap.

Extra equipment:

– Stock control/weigh cells

– Overfill protection device.

– Automatic cleaning of top filter.

– Platform and ladder.

– Multiple level sensors.

– Multiple inspection glasses.

A Bulk Flour System can be part of an overall system with big bag unloading stations and small component systems.

Big bag unloading stations

Big bag unloading stations are used in the same way as silos, where there are simply smaller quantities. Big bag is always delivered according to customer wishes and adapted to the supplier of the products, since there is no standard for big bags. We therefore adapt our unloading station to the current big bag. A big bag system can be included in a total system with silos and small component systems. Big bag unloading stations are available both with electrical lifts and manual lifts.

Minor ingredient systems

A minor ingredient system consists up to 12 containers. There are 8 with a standard volume of 120 liters and 4 with a standard volume of 170 liters. Customized sizes can easily be delivered. The minor ingredient system has a centrally placed weight container where dosing takes place via the auger from the 12 containers. From the weight container, the ingredients are transported via the pneumatic transport system. The minor ingredient system can be included in a total system with silos and big bag stations.

Pneumatic Transport Systems

Pneumatic transport systems are available either as a suction system (vacuum) or a pressure system. The system is designed so that the piping is completely emptied after each filling. Standard capacity: 15 – 100 kg/min Distribution valves are available as accessories so that more weight containers can be controlled by the same system, in-line sieving machines, noise canceling cabinet for capsule, or side channel blowers, etc.

Screw Conveyors

We produce and deliver auger conveyors for different purposes, e.g. in connection with the emptying of silos, big bag unloading stations and small component systems.

Rotary Freeders

We deliver gates in different materials and with different performances (capacity) for use in emptying silos and big bag unloading stations.

Weigh hoppers

We produce and deliver weigh hoppers in stainless steel with the standard sizes 60, 100, 150, 250 and 500 kg. Other sizes on request. Brackets for ceiling mounting are included as standard. In addition, brackets for wall mounting or floor stands are also supplied. All weigh hoppers are fitted with filters and equipped with self-cleaning filters. The weigh hoppers are included as standard with a manual outlet valve, but can also be delivered with an electro-pneumatic outlet valve. The weigh hoppers can be supplied with pneumatic unloading help to ensure that the weight container is completely emptied every time. Additionally, the outlet valve can be supplied with a branch piece so that multiple carts or kneading troughs can be supplied with portioned powders.

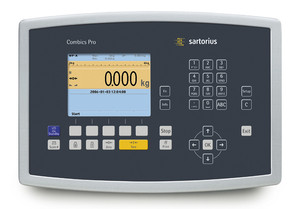

Electronic Preselector Weights

With electronic predetermining weights, the selected product quantity can be automatically weighed

Recipe Management Systems

With recipe management systems, it is possible to prepare recipes. When the recipe is subsequently called up, the desired quantity of finished product should simply be specified, whereupon the system itself pulls the desired product quantities from the various storage devices (silos, big bag unloading stations, small component systems, water mixes, liquid dosing, etc.).

Sifters

Using sifters prevents foreign objects in the flour. The size of the foreign objects that can pass through the sieve machine depends on the size of the mesh of the selected sifters.

The picture shows a configuration with receiver, sifters, day tank, and sack fixture.

The picture shows a turbo sifters.

Liquid Dosing System

We deliver various liquid dosing systems. The displayed image is an ongoing assembly of a syrup dosing system which is delivered as part of a combined system consisting of syrup dosing, flour silos, big bag unloading stations, small component system, and recipe management.

Sour Dough Tank

Process Tank

We deliver day tanks and process tanks in different materials and designs.

Water Mixer

We sell water mixers from different manufacturers and designs for use with our recipe management systems.

Sheet Cleaning Machine

We sell clean machines for cleaning of steel sheets, aluminum sheets, and perforated sheets.